More sustainable biomedical and environmental sensing instruments may be made possible with the use of protein nanowires that are a natural product of the microorganism, Geobacter, which was discovered over 30 years ago in mud from the Potomac River.

Sustainable Electronic Composite Materials:Not Just About Mud An interdisciplinary team at University of Massachusetts Amherst spearheaded the research that shows it is possible to combine protein nanowires with a polymer to produce a new class of flexible electronic composite materials that retain the electrical conductivity and the unique sensing capabilities of the protein nanowires.

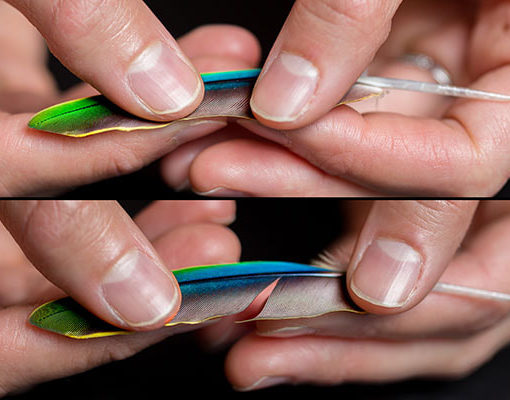

“The finding that protein nanowire networks retain conductivity and sensor response when immersed in a polymer demonstrates the potential for producing a wide diversity of flexible sensor devices with these sustainably produced electronic materials,” said Derek Lovely, PhD, one of the leaders on the project in an interview with Innov8 Updates. Lovely and coworkers discovered the Geobacter species in 1987, the microorganism used to make the protein nanowires, and since found that it has the potential for bioremediation and electricity production. Protein nanowires have many advantages over the silicon nanowires and carbon nanotubes in terms of their biocompatibility, stability, and potential to be modified to sense a wide range of biomolecules and chemicals of medical or environmental interest, according Lovley in a UMass Amherst news release. However, these sensor applications require that the protein nanowires be incorporated into a flexible matrix suitable for manufacturing wearable sensing devices or other types of electronic devices. “We have been studying the biological function of protein nanowires for over a decade, but it is only now that we can see a path forward for their use in practical fabrication of electronic devices,” Lovley said in the release. Postdoctoral research Yun-Lu Sun, now at the University of Texas at Austin, discovered the proper conditions for mixing protein nanowires with a nonconductive polymer to yield the electrically conductive composite material. He demonstrated that although the wires are made of protein, they are very durable and easy to process into new materials. “We can mass-produce protein nanowires with microbes grown with renewable feedstocks. The manufacture of more traditional nanowire materials requires high energy inputs and some really nasty chemicals,” Lovley added in the news release. By contrast, he said, “Protein nanowires are thinner than silicon wires, and unlike silicon are stable in water, which is very important for biomedical applications, such as detecting metabolites in sweat.” Research leader and polymer scientist Todd Emrick, PhD added, “These electronic protein nanowires bear surprising resemblance to polymer fibers, and we’re trying to figure out how to combine the two most effectively.” Todd Emrick and Thomas Russell were responsible for bringing protein nanowires into the materials field. In their proof-of-concept study, the protein nanowires formed an electrically conductive network when introduced into the polymer polyvinyl alcohol, and the system seems to survive harsh conditions. “The protein nanowires can withstand a broad range of pH (1-10.5) and conductivity is actually increased at lower pH,” Lovley said to Innov8 Updates. “The protein nanowires are also stable in a diversity of organic solvents and temperatures up to 120 °C. Within these parameters there is no loss of conductivity over time.” The conductivity of the protein nanowires embedded in the polymer changed dramatically in response to pH, according to the news release. “This is an important biomedical parameter diagnostic of some serious medical conditions,” Lovley explained. “We can also genetically modify the structure of the protein nanowires in ways that we expect will enable detection of a wide range of other molecules of biomedical significance.” Works Consulted

|

|